Core+ stability

An effective system to keep the load more stable at higher speeds.

GH’S SOLUTION: Core+ Stability

- Effective for both trolley travel and crane travel.

- Effective to reduce sway due to both acceleration and braking.

- Touch-screen: Easy configuration and crane monitoring (power consumption, alarms, system faults).

- Easy to retrofit existing cranes. The CORE+ unit is affixed to the electrical panel door.

Advantages

Higher speed + Better accuracy = Increased Productivity and Safety

Hassle-free for operator: System reduces sway automatically.

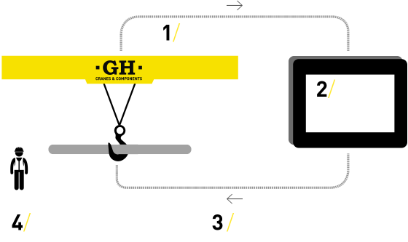

How it works

Inputs from VFDs

CORE+ STABILITY continuously receives following inputs from VFDs:

- Commands from operator (accelerate / decelerate).

- Actual speeds (hoisting, trolley travel and crane travel).

- Vertical position of hook (given by the hoisting motor encoder).

Built-in exclusive Algorithm

Algorithm determines, based on above inputs, optimal acceleration / deceleration rates.

Instructs how to move

Core+ Stability instructs VFDs how to perform the movement.

Back to point 1

Technical details

Bi-directional communication between CORE+ and the VFDs for hoisting, trolley travel and crane travel. Connection via CANopen fieldbus. Software is Upgradable via included USB port. Requires VFDs for all 3 movements, and hoisting motor encoder. Does not require expensive or failure-prone sensors. Maintenance-free. Open-loop control: will not detect / correct sway due to external factors. Automatically disconnects at low-speed motion to ease load positioning. System can be easily connected/disconnected (using touchscreen or optional remote control).