Core+ synchro

Easier and safer handling of large loads using 2 hoists.

GH’S SOLUTION: Core+ Synchro

- Automatically keeps relative distances between hooks. Both horizontally and vertically.

- Works with 2 hoists of same or different capacity, operating in same crane.

- Touch-screen: easy configuration and crane monitoring (power consumption, alarms, system faults).

- Easy to retrofit existing cranes. The CORE+ unit is affixed to the electrical panel door.

Advantages

No need to make manual adjustment of relative position between hooks Increased Productivity and Safety.

- Hassle-free for operator: maintains relative positions automatically.

- Minimal sensor requirement.

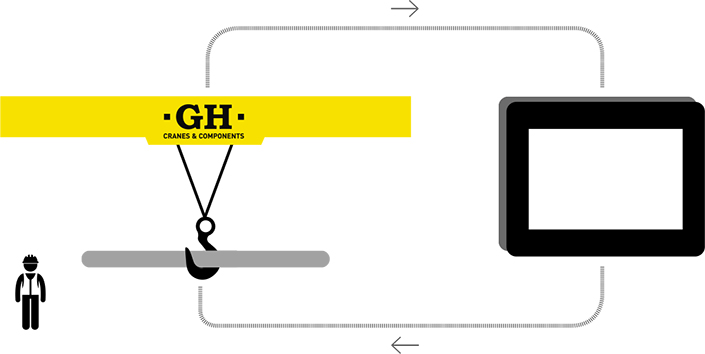

How it works

CORE+ SYNCHRO continuously receives following inputs from VFDs:

- Commands from operator (accelerate / decelerate).

- Actual speeds (hoisting, trolley travel and crane travel).

- Vertical position of each hook (given by the hoisting motor encoder).

• Relative distance between trolleys (given by the laser rangefinder).

Built-in exclusive Algorithm

Algorithm determines, based on above inputs, optimal acceleration / deceleration rates.

Instructs how to move

CORE+ SYNCHRO instructs VFDs how to perform the movement.

Back to point 1

Technical details

Bi-directional communication between CORE+ and the VFDs for hoisting, trolley travel and crane travel. Connection via CANopen fieldbus. - Software is Upgradable via included USB port. - Requires VFDs for all 3 movements, incremental encoder at each lifting motor, and 1 laser rangefinder. - Does not require expensive or failure-prone sensors. Maintenance-free. - Closed-loop control: Maximum error in lifting 10mm. Maximum error in cross travel 50mm. - Works with 2 hoists in the same crane. - System can be easily connected/disconnected (using touchscreen or optional remote control).